GOOD ENERGY SOLUTIONS

Technology

Green Economy

The Future of Sustainable Energy

SOFC

Solid Oxide Fuel Cell

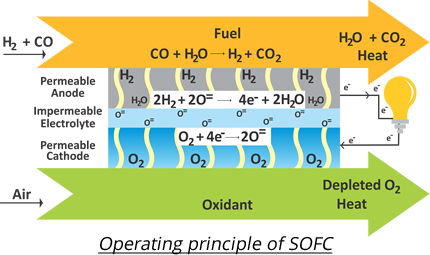

A solid oxide fuel cell (SOFC) is a highly efficient electrochemical device that converts hydrogen and carbon monoxide from hydrocarbon fuels directly into electricity. Solid Oxide Fuel Cells use dense solid oxide as electrolyte material that conduct negative oxygen ions from cathode to anode.

At anode, electrochemical oxidation of hydrogen (H2) or carbon monoxide (CO) takes place and at cathode oxygen reduction reaction takes place

They operate at temperature ranging from 600°C to 1000°C and offer the following key advantages:

Advantages

- Operate at a higher temperature, do not require precious metal catalyst

- Operate on wide variety of hydrocarbon fuels

- Produce the highest electrical efficiency

- Most suited for continuous operation

- Can use heat recovery technologies for a total system efficiency of up to 85 percent

- Near zero emissions and quiet operation, with low maintenance

- Compared to existing generation technologies

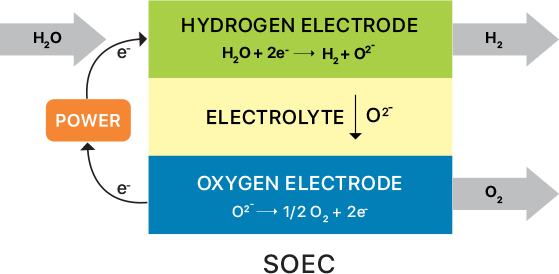

SOEC

Solid Oxide Electrolyser Cell

Key features of SOFC as a SOEC

Compatibility

Environmentally compatible with reduced CO2 emissions in power generation mode

Flexibility

Fuel flexible and sustainable for integration with other energy sources

Capability

Useful for different functions

Adaptability

Suitable for wide variety of applications and adaptable for local energy needs

h2e Power

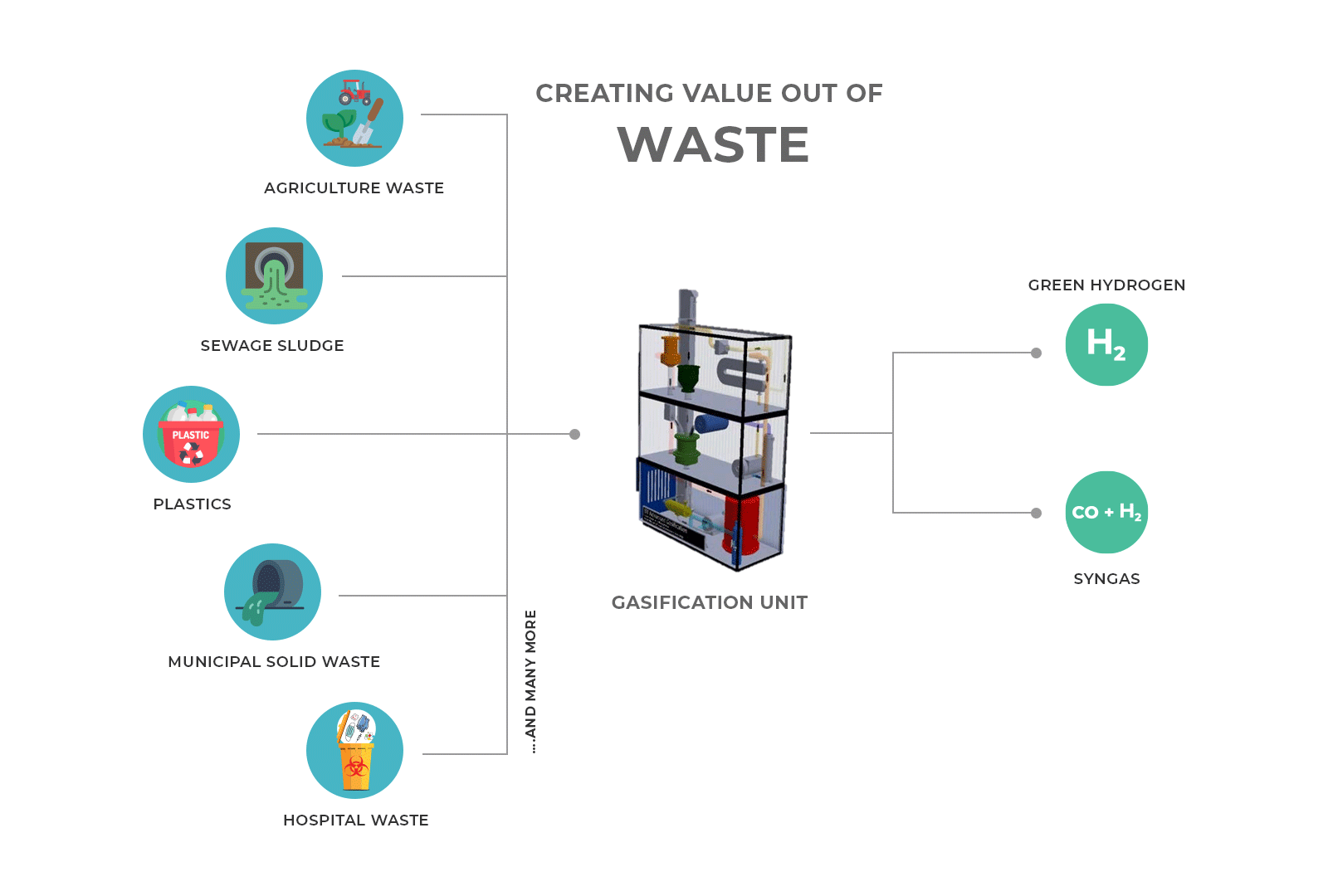

Waste to Hydrogen

h2e collaborated with EPC providers for Waste to hydrogen production. The process creates value out of waste. It is a self-sustainable thermal conversion treatment of organic waste, including plastics, which breaks down the waste matter and extracts the hydrogen they contain. The conversion system addresses the need for decentralized clean energy production for the Energy Smart Grid as well as the growing worldwide need for a source of green, renewable hydrogen for the clean mobility applications. Since it is not incineration, the process does not create or emit hazardous chemical and, unlike conventional gasification solutions, it produces no tar.

One ton per day biomass feedstock yields 50 kg hydrogen per day which can-

• 12 Fuel Cell Vehicle full tanks or

• 40 kW integrated Solid Oxide Fuel Cell