Technology

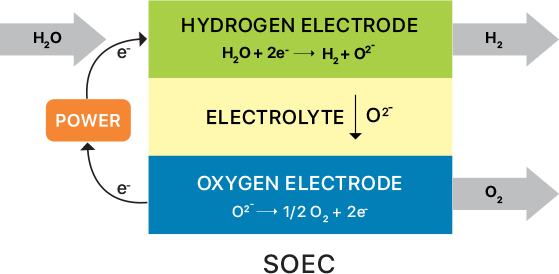

Solid Oxide Electrolyser Cell

SOEC

Solid Oxide Electrolyser Cell

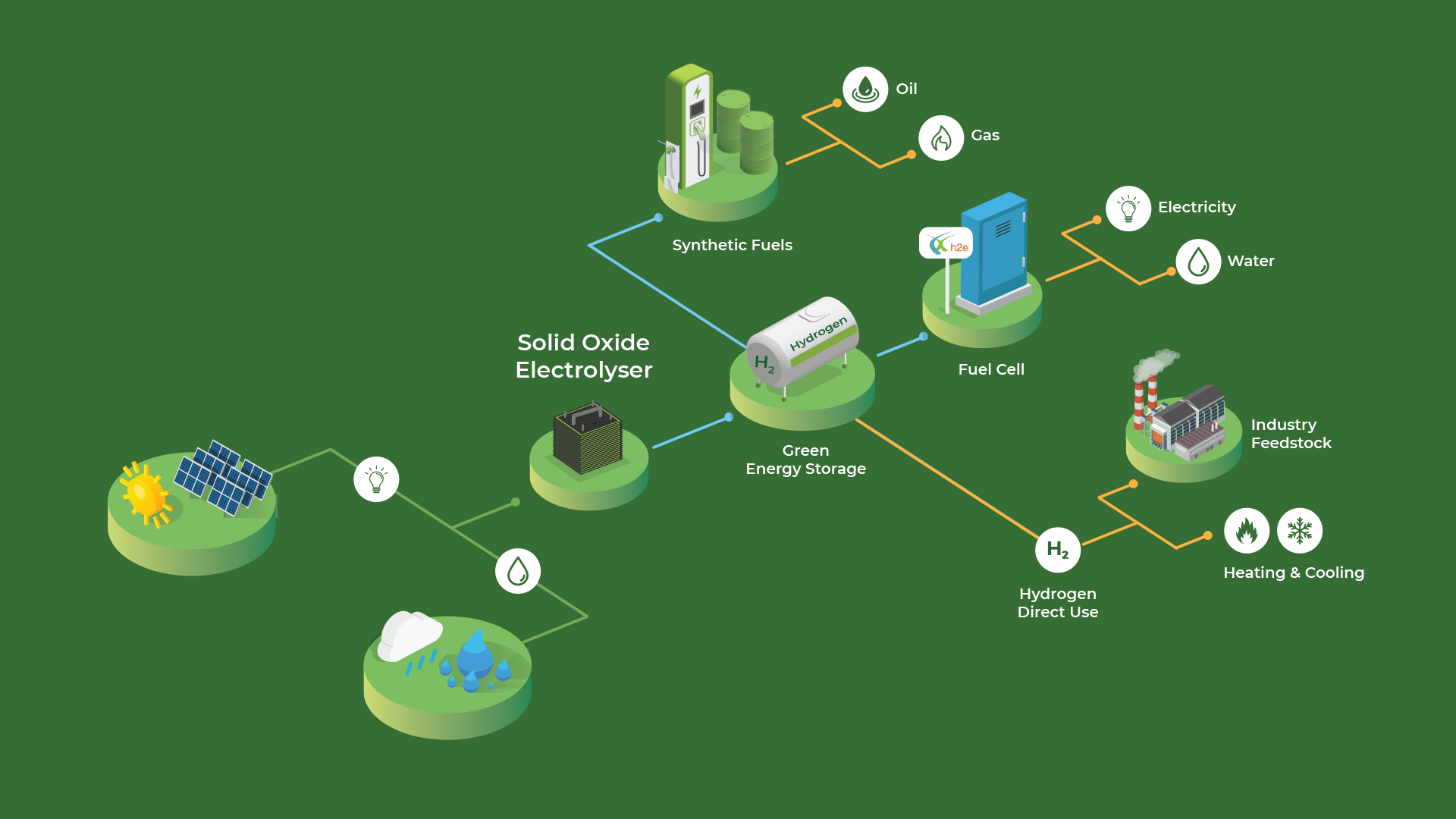

Green Hydrogen - Power to X

Green Hydrogen - Power to X

SOEC

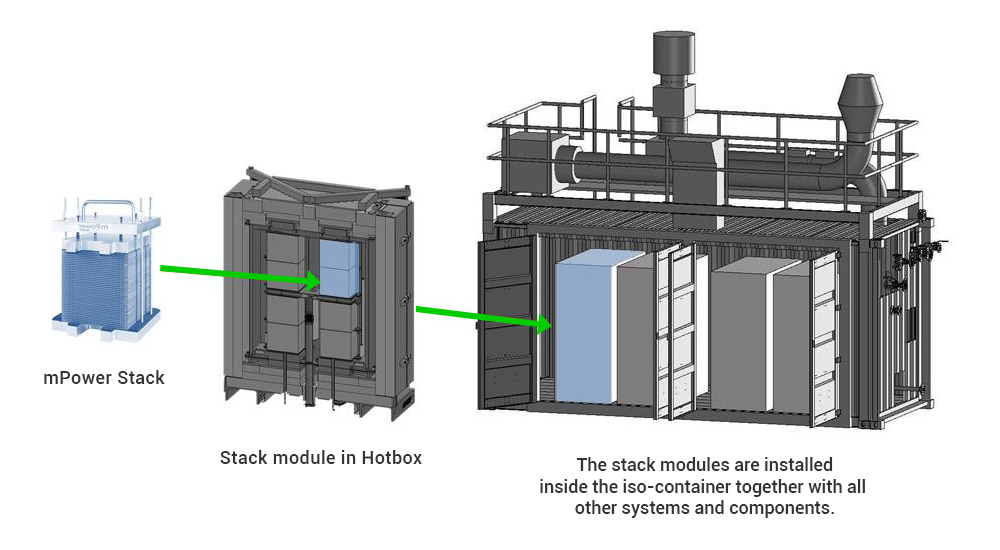

mPower Stack

Currently for green hydrogen production three electrolysis technologies are commercially available. Polymer Electrolyte Membrane electrolysis (PEM), Alkaline electrolysis and Solid Oxide Electrolysis (SOEC) have made remarkable strides for H2 production. SOEC could play a greater role because of the inherent advantages like highest efficiency, highest robustness, no precious metals required for manufacturing, stack made of ceramics which can be sources locally.

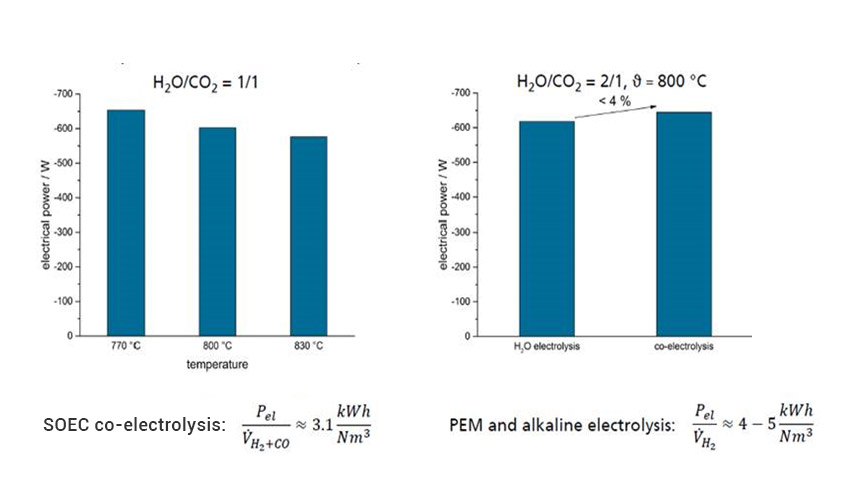

As per the below graphs on the tests conducted using a mPower 10 Cell Stack, through co- electrolysis approx. 1 Nm3 of Syngas can be produced from 3.1 kWh of Electricity. This is efficient than the PEM or Alkaline Electrolysers which needs 4-5 kWh electricity to produce 1 Nm3 of Hydrogen.

SOEC

SOEC UNIT